| 1. Scope of the coverage: |

| This specification is pertinent to the application of insulated

0Ω resistors (designated as RZ). |

| 2 .Temperature range of the application: |

| -55℃ ~ +155℃。 |

| 3. Type: |

| The color of the coating resin for the 0Ω insulated

resistors is gray. |

| 4.Marking and illustration: |

| Two types of designation methods are available for 0Ωinsulated

resistors. One is black ink |

| alphanumeric marking and the other one is color code marking.

The criteria of using either one of |

| the marking methods depend on the size of the resistors

and customers request which is listed in |

| the following: |

| alphanumeric marking ---->1/2W (Fig.1) |

| color code marking ------------>1/6W、1/4W (Fig.2) |

| |

|

| |

| 5.Dimension, voltage, resistance range: listed in

the following Table-1 |

| Rated

power

(W) |

Type |

Resistance (Ω) |

2 2 |

| J ( ±5%) |

L |

Dψ |

ι |

dψ |

| 1/6 |

Normal |

20mΩ以下 |

1.5A |

1.8±0.3 |

28±2 |

0.45±0.05 |

| 1/4 |

Normal |

20mΩ以下 |

2.5A |

2.4±0.1 |

28±2 |

0.60±0.05 |

| 1/2 |

Normal |

20mΩ以下 |

2.5A |

3.0±0.5 |

30±3 |

0.60±0.05 |

|

| |

| 6.Coating |

|

| 6.1 The body of the resistor is covered by nonflammable

silicon resin. |

| 6.2 The maximum length of the lead wire covered by the

resin is 2mm. |

| 6.3 The maximum area of the end cap which is not covered

by the resin is half of the diameter of |

| 6.3 the cap. |

| 6.4 The status of coating condition described by 6.2 and

6.3 are acceptable. |

| |

| 7.Characteristics of electrical performance |

| 7.1 Rated power |

| The rated power indicates the maximum power the resistor

can endure continuously when the |

| ambient temperature is equal to or lower than 70℃. When

the ambient temperature is higher than |

| 70℃, the rated power of the resistor is determined by the

derating curve described in the following |

| figure. |

|

| 7.2 Dielectric strength (Ref. JIS C5202 5.7) |

| Equipment: Dielectric strength tester |

| The body of the resistor is wrapped around by the aluminum

foil without extending beyond the |

| resistor body. Clap one electrode on the aluminum foil

and the other electrode on the lead wire. |

| Apply following voltage from the tester to the resistor

for 1 min.. No flash-over, burning or |

| breakdown should be observed. |

| |

| Wattage |

1/6W |

1/4W |

1/2W |

| Voltage |

300V |

500V |

500V |

|

| |

| 8.Environmental tests |

| 8.1 Load life test (Endurance with rated load) (Ref. JIS

C5202 7.10) |

| Equipment: High temperature chamber and DC power supply |

| The resistors are put in a fixture where no interference

will be allowed. Put the fixture in a 70±3℃ |

chamber and apply rated current in table-1 with a cycle

of 90 min. ON and 30 min. OFF for

|

| hours. After 240, 480, 720 and 1,000 hours, the resistors

are taken out and stabilize at room |

| temperature for 30 min. and then the resistance is measured.

Upon each step of resistance |

| measurement, the change of the resistance should be≦20mΩ

and the appearance should show |

| no remarkable abnormality and legibility of marking. |

| |

| 8.2 Endurance under damp heat and load (Ref. JIS C5202

7.9) |

| Equipment: Constant temperature and humidity chamber, DC

power supply |

| The resistors are put in a fixture where no interference

will be allowed. Put the fixture in a 40±2℃ |

| chamber with RH=90~95% and apply rated current in table-1

with a cycle of 90 min. ON and 30 |

min. OFF for  hours. Water drops should avoid

dripping on the resistors. After 240 and hours. Water drops should avoid

dripping on the resistors. After 240 and |

| 1,000 hours, the resistors are taken out and stabilize

at room temperature for 1 hour and then the |

| resistance is measured. Upon each step of measurement,

the change of the resistance should be |

| ≦20mΩ and the appearance should show no remarkable abnormality

and legibility of marking. |

| |

| 8.3 Temperature cycling (Ref. JIS C5202 7.4) |

| Equipment: High temperature chamber, low temperature chamber |

| Put the resistor to -55℃ chamber for 30 min. then take

it out at room temperature for 2 to 3 min.. |

| Put the resistor to +85℃ chamber for 30 min. then take

it out at room temperature for 2 to 3 min. |

| This completes a cycle. Repeat the cycle 5 times. Put resistors

at room temperature for 90 min. |

| and then measure the resistance. Compare the resistance

before and after test. The acceptable |

| change of resistance is≦20mΩ. The appearance should show

no remarkable abnormality and |

| legibility of marking. |

| |

| 9.Mechanical performance |

| 9.1 Resistance to soldering heat (Ref. JIS C5202 6.4) |

| Equipment: Solder bath |

| Measure the resistance before the test. Immerse part of

the lead wire which is 4±0.8mm away |

| from the body to the flux for 5 - 10 sec. Take the resistor

out and immerse resistors in the solder |

| bath of 350±10℃ for 3.5±0.5 sec.. Stabilize at room temperature

for 1 hour and then measure the |

| resistance value. Compare the resistance values before

and after the test, The acceptable change |

| is ≦20mΩ. |

| |

| 9.2 Solderability (Ref. JIS C5202 6.5) |

| Equipment: Solder bath |

| Immerse part of the lead wire which is 4±0.8mm away from

the body to the flux for 5 - 10 sec. Take |

| the resistor out and immerse resistors in the

solder bath of 245±5℃ for 3.5±0.5 sec. Take the |

| resistor out and inspect the lead wire visually. The acceptable

level is the coverage of the new |

| solder to be 95%. The composition of the solder bath is

99.7% tin and 0.3% Cu. |

| |

| 9.3 Robustness of terminals (Ref. JIS C5202 6.1) |

| 9.3.1 Tensile strength of termination |

| Equipment: Weight gauge |

| Fixed the resistor and apply axially along the lead wire

of 2.5Kg (0.8φ lead wire) , 1.0Kg (0.6φ lead |

| wire) or 0.5Kg (0.45φ lead wire) for 30 sec.. The lead

wire should not break or detached from the |

| resistor and the change of the resistance should be ≦20mΩ. |

| |

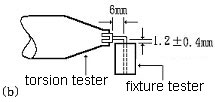

| 9.3.2 Torsional strength |

| Equipment: Torsion tester |

| Bend the terminal 6.4mm away from the body according to

Fig-a to 90 degree with a curvature of |

| 0.75mm~0.80mm. The lead wire should be clamped at a point

of 1.2mm away from the bending |

| point by a fixture which can rotate 360 degree according

to Fig-b. Rotate the resistor 360 degree |

| clockwise and counter clockwise for 1 cycle. The rotation

speed is 360 degree per 5 sec.. Perform |

| 3 cycles for the lead wire diameter of 0.8φ, 1.5 cycles

for that of 0.6φ or 1 cycle for 0.45φ. The |

| terminal should not break down or detached from the body.

The acceptable change of resistance |

| is ≦20mΩ. |

|

| |