| 1. Scope of the coverage: |

| This specification is pertinent to the application of wire

wound resistors (designated as RW). |

| 2 .Temperature range of the application: |

| -40℃ ~ +155℃。 |

| 3. Type: |

| Two types of wire wound resistors are available:

one is normal size and the other one is small |

| size. These two types are distinguished by the color of

the coating resin. The color of the resin for |

| the normal size is gray and that for the small size is

pinkish red. |

| 4.Marking and illustration: ref. To Fig.1, Fig.2: |

| Two types of designation are used to distinguish wire wound

resistors with or without inductance. |

| The one with inductance is: (RWU/S) and the one without

(low) inductance is : (NWU/S). |

| With inductance---------- >1/2W、1W、2W、3W、S1W、S2W、S3W、S5W

(Fig.1) |

| Without inductance ------------>1/2W、1W、2W、3W、S1W、S2W、S3W、S5W

(Fig.2) |

| (without inductance means low inductance or inductance

is <1μH) |

|

|

| |

| 5.Dimension, voltage, resistance range: listed

in the following Table |

| Rated

Power

(W) |

Type |

Resistance Range

(Ω) |

2 2 |

| J ( ±5%) |

L |

Dψ |

ι |

dψ |

| 1/4 |

Normal |

0.1~150 |

6±0.3 |

2.4±0.1 |

28±2 |

0.6±0.05 |

| 1/2 |

Small |

0.1~150 |

6±0.3 |

2.4±0.1 |

28±2 |

0.6±0.05 |

| Normal |

0.1~150 |

9±0.5 |

3.0±0.5 |

30±3 |

0.6±0.05 |

| 1

|

Small |

0.1~330 |

9±0.5 |

3.0±0.5 |

30±3 |

0.8±0.05 |

| Normal |

0.1~330 |

|

4.0±0.5 |

38±3 |

0.8±0.05 |

| 2 |

Small |

0.1~680 |

|

4.0±0.5 |

38±3 |

0.8±0.05 |

| Normal |

0.1~680 |

|

5.5±0.5 |

38±3 |

0.8±0.05 |

| 3 |

Small |

0.1~1K |

|

5.5±0.5 |

38±3 |

0.8±0.05 |

| Normal |

0.1~1K |

|

8.5±0.5 |

38±3 |

0.8±0.05 |

| 5 |

Small |

0.1~1K |

|

8.5±0.5 |

38±3 |

0.8±0.05 |

| 7 |

Small |

0.1~15K |

|

8.5±0.5 |

38±3 |

0.8±0.05 |

| 10 |

Small |

0.1~27K |

8 (MAX) |

44 (MAX) |

38±3 |

0.8±0.05 |

|

| P/S:7W、10W is for Philips specification only. |

| |

| 6.Coating |

|

| 6.1 The body of the resistor is covered by nonflammable

silicon resin. |

| 6.2 The maximum length of the lead wire covered by the

resin is 2mm. |

| 6.3 The maximum area of the end cap which is not covered

by the resin is half of the diameter of |

| 6.3 the cap. |

| 6.4 The status of coating condition described by 6.2 and

6.3 are acceptable. |

| |

| 7.Characteristics of electrical performance |

| 7.1 Rated power |

| The rated power indicates the maximum power the resistor

can endure continuously when the |

| ambient temperature is equal to or lower than 70℃. When

the ambient temperature is higher than |

| 70℃, the rated power of the resistor is determined by the

derating curve described in the following |

| figure. |

|

| 7.2 Rated voltage |

| The rated voltage of a resistor is either a continuous

DC voltage or an AC rms voltage which can |

| be calculated by the following formula. If the calculated

rated voltage is higher than the highest |

| working voltage then the highest working voltage should

be used as the rated voltage. |

P: Rated power (W) R: Nominal resistance

(Ω) E: Rated voltage (V) P: Rated power (W) R: Nominal resistance

(Ω) E: Rated voltage (V) |

| |

| 7.3 Insulation resistance (Ref. JIS C5202 5.6) |

| Equipment: Insulation resistance tester |

| The body of the resistor is wrapped around by the aluminum

foil without extending beyond the |

| resistor body. Clap one electrode on the aluminum foil

and the other electrode on the lead wire. |

| Apply 500V from the tester for 1 min. and the measured

resistance value should be larger than |

| 1,000MW. |

| |

| 7.4 Dielectric strength (Ref. JIS C5202 5.7) |

| Equipment: Dielectric strength tester |

| The body of the resistor is wrapped around by the aluminum

foil without extending beyond the |

| resistor body. Clap one electrode on the aluminum foil

and the other electrode on the lead wire. |

| Apply 500V from the tester to the resistor for 1 min..

No flash-over, burning or breakdown should be |

| observed. |

| |

| 7.5 Short time overload (SOL) (Ref. JIS C5202 5.5) |

| Equipment: S.O.L. tester. |

Apply voltage of  to the resistor for 5 sec., After the test, stabilize the

resistor at room

to the resistor for 5 sec., After the test, stabilize the

resistor at room |

| temperature for 30 min. then measure its resistance.

Compare the resistance before and after the |

| test. The acceptable change of the resistance is: ±(2%+0.05Ω).

|

| |

| 7.6 Flame proof (Ref. JIS C5202 7.12 3.4(2)c) |

| Equipment: AC power supply |

| Apply 2 times, 4 times, 8 times, 16 times and

32 times of rated voltage sequentially. The duration |

| for each voltage application is 1 min.. The resistor

should not demonstrate arcing, burning or melt |

| down except when the applied voltage exceeds 10

times of rated power. Under this circumstance |

| of applied more than 10 times of rated power,

arcing or burning is acceptable but the duration |

| should be less than 5 sec. And the height of flame should

be less than 3.5mmv. |

| |

| 8.Environmental tests |

| 8.1 Load life test (Endurance with rated load) (Ref. JIS

C5202 7.10) |

| Equipment: High temperature chamber and DC power supply |

| The resistors are put in a fixture where no interference

will be allowed. Put the fixture in a 70±3℃ |

chamber and apply rated voltage with a cycle of 90 min.

ON and 30 min. OFF for  hours.

hours. |

| After 240, 480, 720 and 1,000 hours, the resistors are

taken out and stabilize at room temperature |

| for 30 min. and then the resistance is measured. Upon each

step of resistance measurement, the |

| change of the resistance should not exceed ±(5%+0.05Ω)

and the appearance should show no |

| remarkable abnormality and legibility of marking. |

| |

| 8.2 Resistance to damp heat (Ref. To JIS C5202 7.2) |

| Equipment: Constant temperature and humidity chamber |

| The resistors are put in a 40±2℃ chamber with RH=90~95%

for 240±4 hours. After the test, take |

| the resistors out and stabilize in room temperature for

1 - 4 hour. Measure the resistance. The |

| acceptable change of resistance should not exceed ±(2%+0.05Ω)

and the appearance should |

| show no remarkable abnormality and legibility of marking. |

| |

| 8.3 Endurance under damp heat and load (Ref. JIS C5202

7.9) |

| Equipment: Constant temperature and humidity chamber, DC

power supply |

| The resistors are put in a fixture where no interference

will be allowed. Put the fixture in a 40±2℃ |

| chamber with RH=90~95% and apply voltage equal 1/10 of

rated power with a cycle of 90 min. ON |

and 30 min. OFF for  hours. Water drops should avoid dripping on the resistors.

After 240

hours. Water drops should avoid dripping on the resistors.

After 240 |

| and 1,000 hours, the resistors are taken out and stabilize

at room temperature for 1 hour and then |

| the resistance is measured. Upon each step of measurement,

the change of the resistance |

| should not exceed ±(5%+0.05Ω) and the appearance should

show no remarkable abnormality and |

| legibility of marking. |

| |

| 8.4 Temperature coefficient (TCR) (Ref. JIS C5202 5.2) |

| Equipment: High temperature chamber |

| Measure the resistance at room temperature. Put the resistor

in a chamber with the temperature |

| of RT+100℃ for 30 - 45 min. to stabilize. Measure the resistance

again. Compare the resistance |

| at these two temperatures with the following equation and

the acceptable value is: |

| ≦1Ω±500 PPM/℃ or >1Ω±300 PPM/℃ |

|

| R = Resistance at T T = RT + 100℃ Ro = Resistance at To

To =room temperature |

| |

| 8.5 Thermal shock |

| Equipment: DC power supply, low temperature chamber |

| Measure the resistance at room temperature then take it

to -30 ℃ low temperature chamber for 15 |

| min.. Take it out and stabilize at room temperature for

2 hours. Measure he resistance . Compare |

| the resistance before and after test. The acceptable change

of resistance is ±(2%+0.05Ω). The |

| appearance should show no remarkable abnormality and legibility

of marking. |

| |

| 8.6 Temperature cycling (Ref. JIS C5202 7.4) |

| Equipment: High temperature chamber, low temperature chamber |

| Measure the resistance before the test. Put the resistor

to -55℃ chamber for 30 min. then take it |

| out at room temperature for 2 to 3 min.. Put the resistor

to +85℃chamber for 30 min. then take it |

| out at room temperature for 2 to 3 min. This completes

a cycle. Repeat the cycle 5 times. Put |

| resistors at room temperature for 90 min. and then measure

the resistance. Compare the |

| resistance before and after test. The acceptable change

of resistance is ±(1%+0.05Ω). The |

| appearance should show no remarkable abnormality and legibility

of marking. |

| |

| 9.Mechanical performance |

| 9.1 Resistance to soldering heat (Ref. JIS C5202 6.4) |

| Equipment: Solder bath |

| Measure the resistance before the test. Immerse part of

the lead wire which is 4±0.8mm away from |

| the body to the flux for 5 - 10 sec. Take the resistor

out and immerse resistors in the solder bath of |

| 350±10℃ for 3.5±0.5 sec.. Stabilize at room temperature

for 1 hour and then measure the |

| resistance value. Compare the resistance values before

and after the test, The acceptable change |

| is ±(1%+0.05Ω) |

| |

| 9.2 Solderability (Ref. JIS C5202 6.5) |

| Equipment: Solder bath |

| Immerse part of the lead wire which is 4±0.8mm away from

the body to the flux for 5 - 10 sec. Take |

| the resistor out and immerse resistors in the

solder bath of 245±5℃ for 3.5±0.5 sec.. Take the |

| resistor out and inspect the lead wire visually.

The acceptable level is the coverage of the new |

| |

| 9.3 Robustness of terminals (Ref. JIS C5202 6.1) |

| 9.3.1 Tensile strength of termination |

| Equipment: Weight gauge |

| Fixed the resistor and apply axially along the lead wire

of 2.5Kg (0.8φ lead wire) or 1.0Kg (0.6φ |

| lead wire) for 30 sec.. The lead wire should not break

or detached from the resistor and the change |

| of the resistance should be less than ±(0.5%+0.05Ω). |

| |

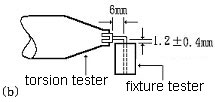

| 9.3.2 Torsional strength |

| Equipment: Torsion tester |

| Bend the terminal 6.4mm away from the body according to

Fig-a to 90 degree with a curvature of |

| 0.75mm~0.80mm. The lead wire should be clamped at a point

of 1.2mm away from the bending |

| point by a fixture which can rotate 360 degree according

to Fig-b. Rotate the resistor 360 degree |

| clockwise and counter clockwise for 1 cycle. The rotation

speed is 360 degree per 5 sec.. Perform |

| 3 cycles for the lead wire diameter of 0.8φ and 1.5 cycles

for that of 0.6φ. The terminal should not |

| break down or detached from the body. The acceptable change

of resistance is ±(0.5%+0.05Ω). |

|

| |